Introduction to Extrusion

Extrusion plays a prominent part on the plastics industry. Extrusion is a continuous process, and can be adapted to produce a wide variety of finished or semi-finished products, including pipe, profile, sheet, film and covered wire.

Extruder

Extruder is the most important part of Extrusion line. In order to produce satisfactory extrudate it is necessary to apply heat to the granules in order to soften them and make the resulting melt capable of flow under some pressure. This is carried out rotated in the barrel by means of gear box and variable screw drive or Eddy current motor.

Therefore the screw barrel has following functions :

- pumping

- heating

- mixing

- pressurizing

- feed zone at hopper end

- compression zone (transition) at the middle

- melt zone (melting zone) at the die end

The maximum delivery of granules by the feed section may be achieved by :

- A relatively deep channel

- a low degree of friction between the granules and screw

- a high degree of friction between granules and barrel wall

- an optimum helix angle (20 degree for LDPE)

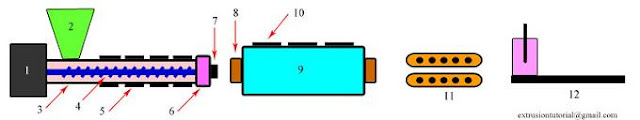

Parts of the Extrusion Line

You can get small idea about Extrusion line from following image.

Parts

- Screw Motor System

- Hopper

- Screw Barrel

- Screw

- Heaters & Thermocouple

- Land & Core

- Die

- Vacuum Calibration System

- Calibration & Cooling Bath

- Bath Doors

- Haul-Off System

- Cutting System

Control Dimensions & Defects

At Pipe Extrusion,Dimensions

- Increase or Decrease Mean Outer Diameter : Controlling Vacuum Pressure

- Increase or Decrease Wall Thickness : Controlling Haul-Off (Puller) Speed

- Increase or Decrease Length : Controlling Cutting System Limiter

Defects

Ballooning :

If there is a Haul-off speed variation, some parts of pipe will increase Outer Diameter. This is the Ballooning. Then you have to adjust Haul-off .

Ripples :

If you facing this defect, you have to control Calibration & Vacuum.

Grooved Lines :

If you facing this defect, first you can use Purge Compound. But if defect continued, you have to control Die system.

Holes :

If you facing this defect, first you can speed-down the Haul-off. But if defect continued, you have to control PVC Compound by controlling Filler content.

Tweet

If you have any suggestions or any information about PVC, PVC processing, PVC products, etc.. that useful to other members, please mail me or put it as a comment. I will post it in this blog with your details.

ReplyDeleteOur offered conical screw barrel is manufactured under the standardized supervision of various software and modern technology. Every Screw barrel goes through quality professional and regular quality testing. We don’t compromise with our quality of screw barrel. Contact Us: 9924204501

ReplyDeleteScrew barrel manufacturer in Ahmedabad : Our offered screw barrel is manufactured under the standardized supervision of numerous software and up-to-date technology. Every Screw barrel goes through superiority professional and regular quality testing. We don’t compromise with our quality of screw barrel manufacturing. Contact Us: 9924204501

ReplyDelete